Service to optimize energy efficiency

Did you know that up to 2.5% of the world’s CO2 emissions could be prevented if heat exchangers performed optimally and were serviced regularly? Reducing carbon emissions is a vital step towards decarbonization and is just one of the benefits of regular service.

With Alfa Laval as your service partner, you will gain access to expert support throughout your products’ lifetime, optimizing heat transfer efficiency and saving energy on-top of carbon emissions.

Save energy and emissions by Service

With energy efficiency accounting for up to 40% of the energy savings we need to reach net zero, we need to make sure that processes are optimized with regular maintenance. Watch this short video to see how Alfa Laval’s services can save energy and reduce emissions for your processes.

Watt’s it worth?

Every year, Alfa Laval install and service millions of heat exchangers, reducing capacity needs by 100 GW.

To put that into perspective, the global wind power capacity from newly installed wind turbines was 93 GW in 2021.

Imagine what we could achieve if all industries and applications optimized energy efficiency to save energy and carbon emissions.

The value of service

Heat exchangers are often thought of as static equipment, but it is important that you do not neglect service. Serving your heat exchangers at the recommended intervals will optimize energy efficiency, reduce carbon emissions, improve productivity, and reduce the total cost of ownership.

Due to fouling build up, heat transfer efficiency and equipment performance reduces over time. This results in increased energy consumption, carbon emitted, and operation expenses.

With regular maintenance, you can reduce the impact of fouling, increasing energy efficiency, lowering energy consumption, emitting less carbon, and optimizing life cycle costs.

Here’s the proof

Want to know how much you could save in your industry?

Our experts have been working with partners all over the world to find the data we need to support all industries and applications, on the road to net zero.

Read our proof packs to find out about your energy efficiency opportunities or contact us today.

Energy Hunter – On the hunt for residual energy

Everyone can improve the energy efficiency of their processes. Just look for areas of improvement and reduce wasted energy. Alfa Laval has the technology, expertise and service to maximise the efficiency of your heat transfer. So what are you waiting for? Use our new tool to calculate how much you can save today.

Visual Condition Assessment

We understand the importance of shared knowledge and collaboration when it comes to reaching global sustainability targets. That is why we teamed up with Microsoft to develop a new thermal image recognition APP that puts customers in full control of their own energy efficiency monitoring. The combination of Alfa Laval's extensive service knowledge and Microsoft’s AI software makes it possible for our customers to check the maintenance needs of their Alfa Laval plate heat exchangers with just their smart phone.

Heat transfer Service offering

Plate heat exchangers

For customers in heavy process industries, the right heat exchanger can make production more sustainable, reliable, and economical. Continual, short-interval service is the key to keeping your heat exchangers running atop capacity and efficiency.

Compabloc

Alfa Laval Compabloc is perfect for tough media, pressure or temperature demands. It’s also backed by a global network of experienced experts, as well as a truly comprehensive service guarantee that helps keep it running efficiently and sustainably, so you can save energy, money and CO2 emissions.

Packinox

Choosing Packinox means using the best solution to reach an outstanding heat recovery, with a thermal efficiency above 95%. Every Packinox heat exchanger is fully customized as per your exact operating conditions. Built for maximum uptime, Packinox comes with a complete service offering supporting your energy efficiency goals.

Wet Surface Air Coolers (WSAC)

Alfa Laval WSACs are heavy-duty by design, and can sustain pressures up to 2500 psi. These units provide maximum cooling in a compact unit and use a minimum of water and electric power. Continual, short-interval service can help you save even more fuel and CO2 emissions with your WSAC technology.

Spiral heat exchangers

Alfa Laval has more than a half-century of experience with spiral technology, as well as a worldwide network of local service experts. With continual, short-interval service to keep you heat exchanger running at top capacity and efficiency, you can count on your spiral heat exchanger to deliver truly sustainable uptime in the toughest duties while cutting CO2.

Air cooled exchangers (ACE)

Alfa Laval air cooled exchangers are built for reliable operation in demanding applications. These robust systems provide high performance with very low energy consumption. Extensive service offering includes all brands of air cooled exchangers.

Watt’s it worth?

Every year, Alfa Laval install and service millions of heat exchangers, reducing capacity needs by 100 GW.

To put that into perspective, the global wind power capacity from newly installed wind turbines was 93 GW in 2021.

Imagine what we could achieve if all industries and applications optimized energy efficiency to save energy and carbon emissions.

Find out how you can save energy in your processes here.

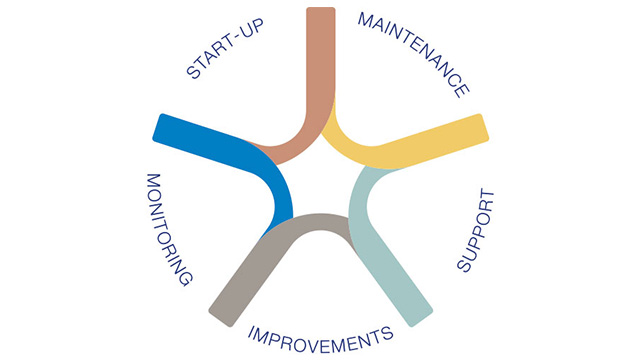

360° of service

Our global service network has dedicated specialists, knowledgeable about your industry. We are here to support you with parts and expertise, wherever and whenever you need them.

The Alfa Laval 360° Service Portfolio covers all your needs throughout the life cycle of your equipment — from start-up, maintenance, support and improvements to monitoring services — for maximum uptime, availability and optimization.

By minimizing your total cost of ownership, we help you stay ahead of the competition.

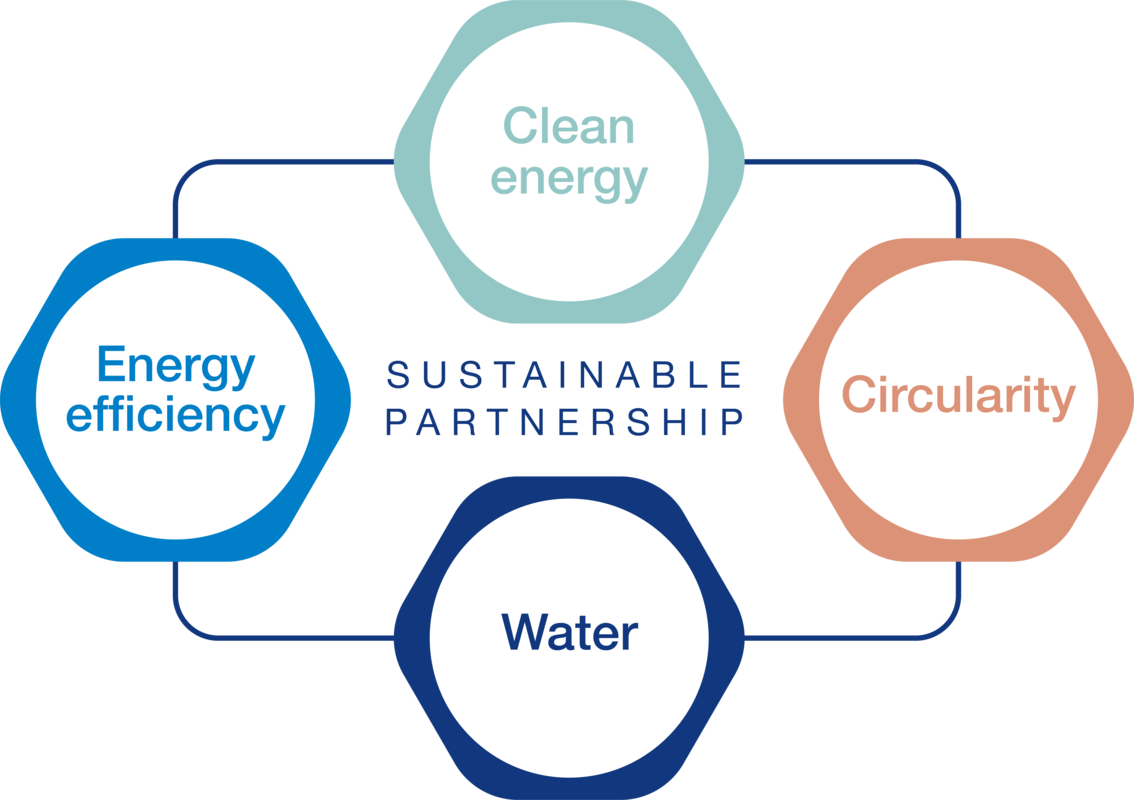

Wydajność energetyczna

Czysta energia

Skontaktuj się z nami

Dowiedź się więcej na temat naszych zrównoważonych rozwiązań