2024-11-13 Produkty

Alfa Laval technology lays foundations for meeting rising demand for sustainable aviation fuel by means of advanced feedstock

Alfa Laval has won a contract to supply innovative pretreatment technology that will be key to producing hundreds of thousands of tonnes of sustainable aviation fuel (SAF) every year at southern Europe’s largest biofuel facility.

Construction on a new plant at the facility in Huelva, Spain, began in February this year, and once up and running in 2026, it will represent a groundbreaking move to increase biofuel production to meet increasing global demand for SAF, delivered by a joint venture Cepsa Bioenergia San Roque (CBSR) between Cepsa and Bio-Oils Energy, part of Apical Group.

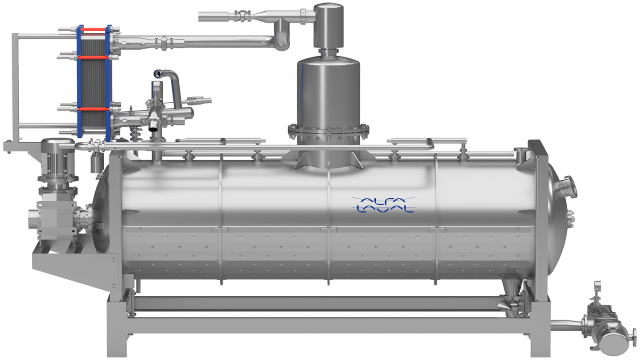

Alfa Laval contributes to this 1.2-billion-euro project by supplying two different pretreatment units for the plant. The construction of the plant is an important step on the journey towards decarbonizing the global transport sector in a sustainable manner, while creating more than 2,000 direct and indirect jobs in the process.

“It means a lot to have this degree of trust placed in Alfa Laval, delivering key solutions that will be the foundations of a project that has seen huge investment,” says Bent Sarup, Vice president, Oils & Fats Systems BU Food Systems. “It’s a very significant order for us and reinforces our reputation as real leaders and experts in this vitally important area.”

The new plant at Palos de la Frontera, will produce 500,000 tonnes of SAF and renewable diesel annually from advanced feedstock – which comes from agricultural waste, fats, oils and greases. This is important in terms of sustainability as these are products that do not impact on the global food supply, which means that the rising demand for biofuel can be met without hampering the efforts to feed the world’s growing population.

Alfa Laval is supplying two pretreatment units for two separate lines with similar capacities at CBSR, one which processes multiple feedstocks and one that focuses on used cooking oils and palm waste oils.

This allows for flexibility and future-proofing, as Andrew Logan, Regional Business Manager – Europe, Oils & Fats Systems, explains: “The two systems make for a flexible overall solution as it can deal with complex or simplified pretreatment, depending on the feedstock involved. Looking into the future, no one knows what feedstock will be available, so building in flexibility like this is absolutely key.”

The new plant means that overall Cepsa and Bio-Oils Energy will be doubling their total renewable fuels production capacity at the facility to one million tonnes a year.

Executive Director of parent company Apical, Pratheepan Karunagaran, says: "Our 2G biofuels plant with Cepsa, which will be the largest aviation fuel processing facility in southern Europe, is an excellent example of how industry players can come together to unlock the potential of SAF and scale up adoption in an affordable manner.”

Biofuels are crucial in decarbonizing transport into the future by providing a low-carbon solution for existing technologies and the global production of SAF is expected to triple in 2024, compared to the 2023 levels, reaching 1.5 million tonnes. According to the International Energy Agency (IEA), the use of advanced feedstock in producing this fuel must increase to 40% by 2030 – up from 9% in 2021 – to help meet this demand while minimizing impacts on the global food supply and land-use.

Maarten Wetselaar, Cepsa CEO, highlighted: “Today we are breaking ground on our second-generation biofuels plant, the first major milestone of our Positive Motion strategy. This strategic project for Spain and Andalusia will make us a European benchmark in the field of green molecules and facilitate the immediate decarbonization of sectors that cannot run on electrons, like aviation. This is the start of a new chapter for Cepsa and this region that will generate quality employment and a new era of industrialization”

The IEA’s Net Zero Scenario also states that over 10% of fuel consumption in aviation needs to be SAF by 2030 to stay on course for net zero CO2 emissions by 2050. In 2022, the International Air Transport Association estimated global SAF production to make up only around 0.1% to 0.15% of total jet fuel demand.

As well as supplying this crucial much-needed biofuel, the new facility will also emit 75% less CO2 than a traditional biofuel plant and is designed to achieve net zero emissions in the medium term. using 100% renewable electricity and different heat recovery and energy efficiency systems. It will only use reclaimed water, and its water emissions will have a minimal impact on the ecosystem thanks to a powerful water treatment plant.

More information: Hydrotreated vegetable oil pretreatment system | Alfa Laval

About Alfa Laval

The ability to make the most of what we have is more important than ever. Together with our customers, we’re innovating the industries that society depends on and creating lasting positive impact. We’re set on helping billions of people to get the energy, food, and clean water they need. At the same time, we are decarbonizing the marine fleet that is the backbone of global trade.

We pioneer technologies and solutions that free our customers to unlock the true potential of resources. As our customers’ businesses grow stronger, the goal of a truly sustainable world edges closer. The company is committed to optimizing processes, creating responsible growth, and driving progress to support customers in achieving their business goals and sustainability targets. Together, we’re pioneering positive impact.

Alfa Laval was founded 140 years ago, has customers in some 100 countries, employs more than 21,300 people, and annual sales in 2023 were SEK 63.6 billion (5.5 BEUR) in 2023. The company is listed on Nasdaq Stockholm.

Contact

Bent Sarup

VP Oils & Fats

Alfa Laval BU Food Systems

Kamilla Kjørup Boe

Marketing Communications Manager

Alfa Laval BU Food Systems

mobile: +45 3178 6642