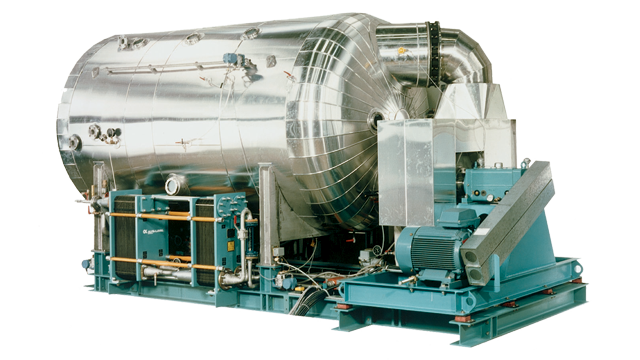

VVC - Mechaniczny kompresor oparów

Alfa Laval distillation equipment converts seawater and brackish water into high purity water for use in industries such as power plants, oil & gas off-shore platforms, refineries, food production and mining as well as at remote on-shore locations.

Meeting future demands

Alfa Laval has developed two concepts which have proven to be the most reliable process for desalination of high salinity waters. The first concept is based on the multi-effect process, which is thermally driven and applicable where low cost or free thermal energy is available. The second concept is based on the mechanical vacuum vapour compression process, which is electrically driven and is remarkably efficient and robust.

Using our extensive experience and know-how Alfa Laval constantly works to improve and refine both the process and the design of our desalination equipment. As a result Alfa Laval plate type desalination units are the most robust, reliable and easy to operate and maintain on the market today.

Features and benefits

VVC offers high fresh water capacity with small installation footprint and low weight which is of high importance for easy installation and when space is limited.

The VVC design offers more features and benefits, for example:

- Titanium plate type evaporators for long lifetime without corrosion

- Full access to evaporator heat transfer surfaces

- 100% performance recovery after cleaning

- Lowest total water production costs with mechanical Vacuum Vapour Compressor

- Highest availability

- Simple and full automatic operation & easy maintenance

- High quality distillate for boiler feed, process water and potable water

Pioneer within desalination

Alfa Laval has supplied desalination units since the 1950s and today is one of the leading companies in the desalination business with more than 45 years experience and over 30,000 successful desalination units - many of these are still in operation.

Zasada działania

Vapour compression refers to a distillation process where the pure vapour evaporation from sea water is achieved by the application of heat from the condensation of the compressed vapour.

Vacuum Vapour Compression Process

The effect of compressing water vapour is obtained by means of an electrically driven, mechanical centrifugal compressor. The saline water is evaporated at sub-atmospheric pressure on one side of the heat transfer surface, and on the opposite side it is condensed into fresh water which is collected and extracted as product water.

The VVC process operates under vacuum and is the most efficient distillation process available in the market today in terms of energy consumption and water recovery ratio. As an electrically driven process it is considered to be a "clean" system. Due to its high efficiency Vacuum Vapour Compression Distiller is the obvious choice for a single stand-alone purpose for smaller capacities.

Special features of VVC plants with titanium plates

- Corrosion resistant due to high-grade titanium evaporators

- Compact design with low weight and footprint due to high thermal efficiency of the PHE design

- Controlled thin falling film avoiding dry spots, thereby avoiding scaling

- Short residence time of the media in a PHE unit resulting in faster process response and less scaling

- Easy maintenance - CIP cleaning as well as fully mechanical cleaning is possible

A special feature for desalination units

A special challenge for desalination units with concentrated sea water at high temperature is to avoid corrosion and formation of scaling. A dedicated plate design of the heat transfer areas for VVC and MED units have been developed with special focus on evaporation of sea water by using Alfa Laval's corrugated plate heat exchanger technology using high grade titanium material.